Essential Maintenance Guide for Industrial Hose Clamps

Maintenance Team

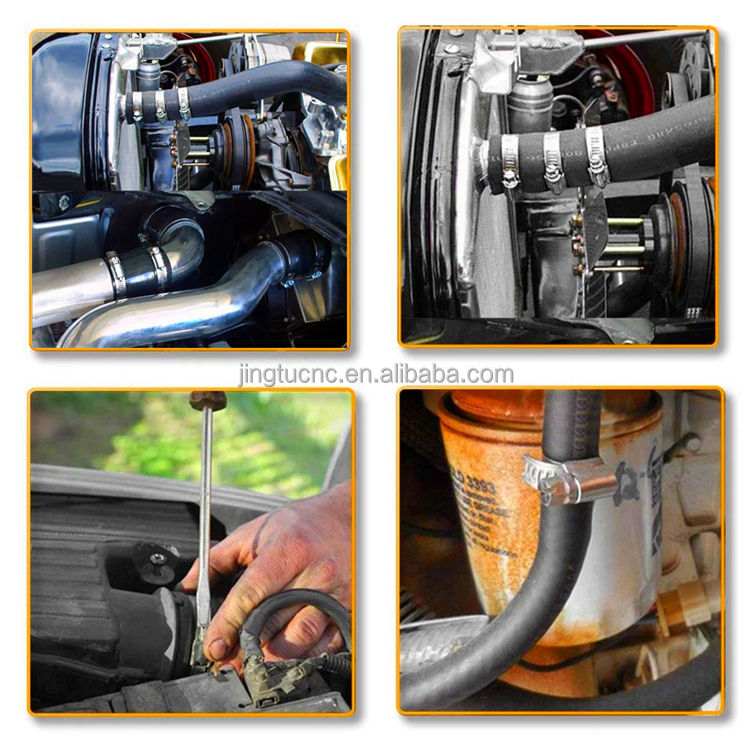

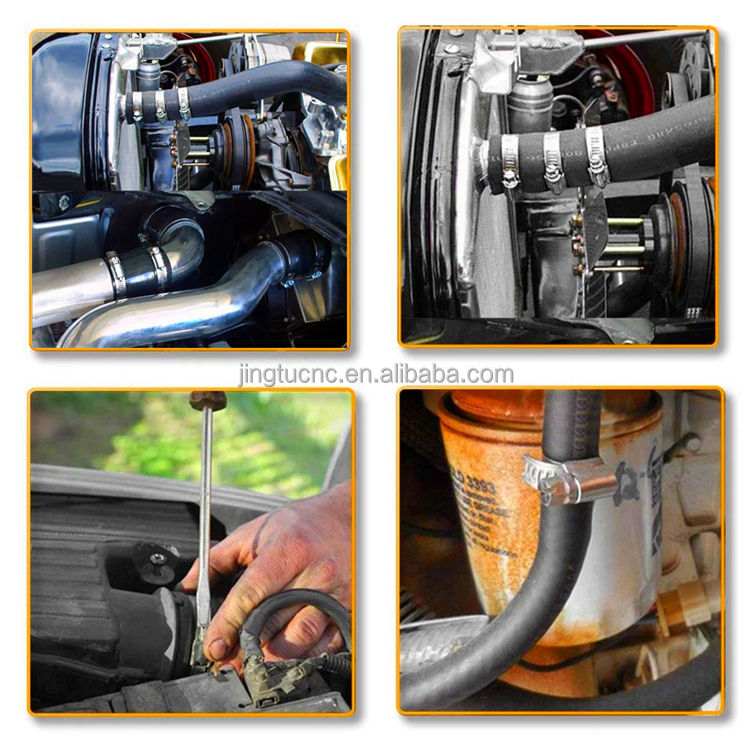

Essential Maintenance Guide for Industrial Hose Clamps

Example 1: Preventable Failure

A manufacturing facility experienced an unexpected production stoppage when a poorly maintained hose clamp failed:

- 8 hours of downtime

- $50,000 in lost production

- Emergency replacement costs

- Unplanned maintenance scheduling

Explanation: Proper Maintenance Procedures

1. Regular Inspection Schedule

- Weekly visual checks

- Monthly torque verification

- Quarterly detailed inspection

- Annual replacement assessment

2. Key Inspection Points

- Corrosion signs

- Band integrity

- Screw/bolt condition

- Seal effectiveness

3. Documentation Requirements

- Inspection dates

- Findings

- Actions taken

- Follow-up items

Example 2: Maintenance Success

Chemical Plant Implementation

A chemical processing facility implemented our maintenance program:

- Zero unplanned downtime

- 40% reduction in replacement costs

- Extended clamp lifespan

- Improved safety compliance

Marine Application Results

A cargo ship fleet adopted our maintenance protocol:

- Eliminated salt-water corrosion issues

- Reduced emergency repairs by 75%

- Standardized maintenance procedures

- Improved crew safety

Action Plan

-

Implement Inspection Program

- Create inspection checklist

- Train maintenance staff

- Set up documentation system

- Establish response procedures

-

Maintain Proper Tools

- Calibrated torque wrenches

- Cleaning supplies

- Inspection equipment

- Replacement parts inventory

-

Follow Best Practices

- Clean before inspection

- Check for proper torque

- Document all findings

- Address issues immediately

Need Help Setting Up Your Maintenance Program?

Our technical team can help you develop a customized maintenance plan for your specific application.